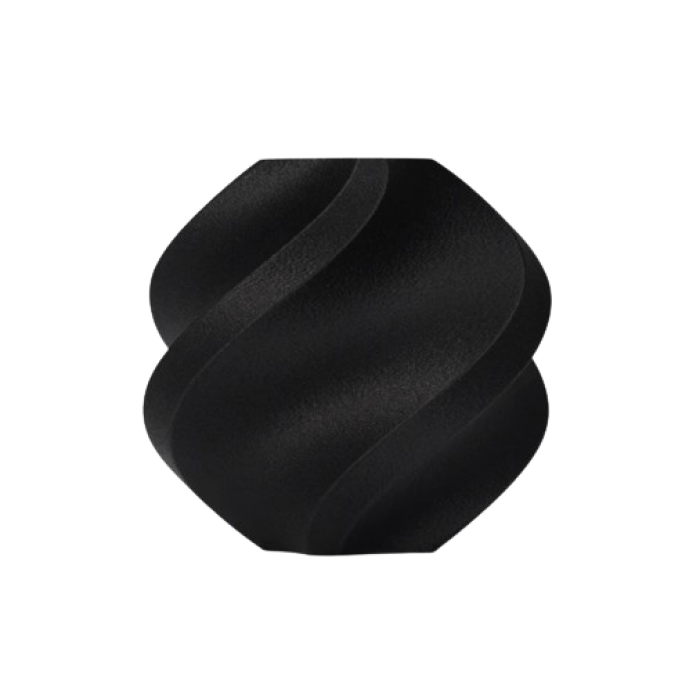

eTPU 95A

TPU material has good flexibility with a hardness of 95A, easy to print, and can quickly print large, complex and accurate prototypes of elastomer parts.Excellent elasticity, printed products with tpu filament are not easy to deform.

Product Features

Features

- Flexible and durable

- High impact strength

- Exceptional wear properties

- Tear resistant

- Low shrinkage

- Good dimensional stability

Shipping Weight

- 1.400 Kg

Description

TPU Filament: Unleashing the Power of Flexibility and Durability

Exploring the Versatility of TPU Material

In the ever-evolving world of 3D printing, the choice of materials plays a pivotal role in determining the success of your projects. Enter TPU (Thermoplastic Polyurethane), a filament that stands out for its exceptional flexibility, sturdiness, and a myriad of applications that redefine the possibilities in 3D printing.

1. Flexible and Soft: The TPU Advantage

TPU material takes flexibility to new heights, offering a unique combination of softness and pliability. This characteristic makes it ideal for projects where flexibility is key, ensuring that your prints can bend and stretch without compromising structural integrity.

2. Sturdy and Durable: Withstanding the Test of Time

TPU filament doesn't just stop at flexibility; it brings a robust and durable dimension to your prints. Whether you're crafting prototypes, functional parts, or even insoles, TPU's sturdiness ensures that your creations withstand the test of time and usage.

3. High Toughness: Resilience Redefined

The high toughness of TPU material sets it apart in the world of 3D printing. Experience prints that can endure challenging conditions, exhibiting resilience that goes beyond conventional filaments. TPU brings a new level of toughness to your creations.

4. High Impact Resistance: Prints That Withstand Pressure

When it comes to impact resistance, TPU filament excels. Your prints are not just flexible and tough; they can also absorb and disperse impact forces, making them suitable for a wide range of applications, from functional prototypes to protective gear.

TPU Printing: Tips for Optimal Results

Before you embark on your TPU printing journey, consider the following tips to achieve the best results:

-

Optimal Drying Conditions: To achieve the best printing effect, it's recommended to dry the TPU filament at 55℃ for more than 4 hours before printing. This ensures that the filament is in prime condition for your printing projects.

-

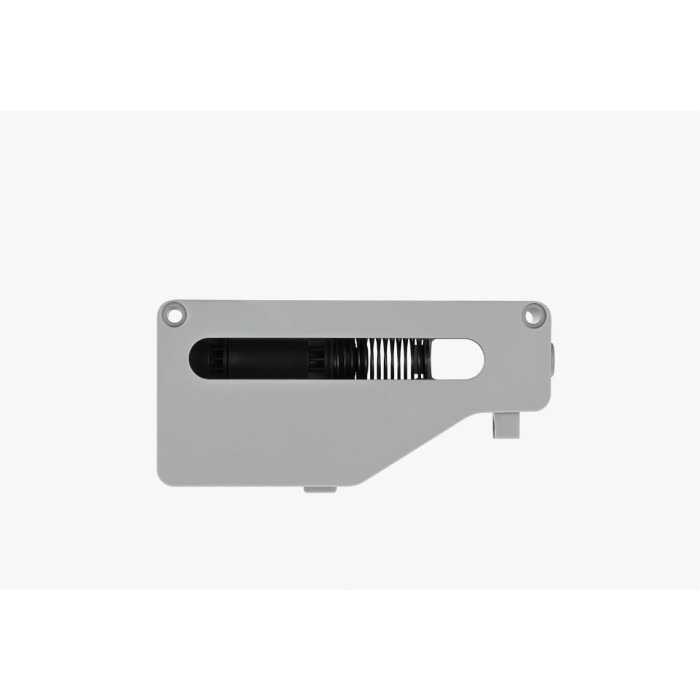

Compatible Cartridges: For seamless printing, use TPU with eBOX cartridges. This compatibility enhances the overall printing experience and ensures optimal results.

-

Extruder Considerations: TPU is best printed with a short-range two-wheel reduction extruder designed for flexibility. The use of eTPU-95A materials may pose challenges on remote extrusion machines, but adjusting print speed can improve outcomes.

-

Nozzle Maintenance: Prolonged printing may result in impurities in the nozzle. Combat this by using a cleaning filament, and if necessary, replace the nozzle and throat with new ones to maintain print quality.

Redefine Your Prints with TPU Excellence

In conclusion, TPU filament emerges as a versatile and indispensable material for 3D printing enthusiasts. From flexibility and toughness to impact resistance, TPU opens doors to a new realm of possibilities. Follow the recommended tips for optimal printing, and embark on a journey where your prints embody the perfect blend of flexibility, sturdiness, and durability that TPU brings to the table. Elevate your projects with TPU excellence, where every print tells a story of innovation and resilience.

Specification

Recommended Printing Parameters

.png)

-3.png)

-14.png)

-1.png)

-8.png)

-2.png)

-2.png)

-1.png)

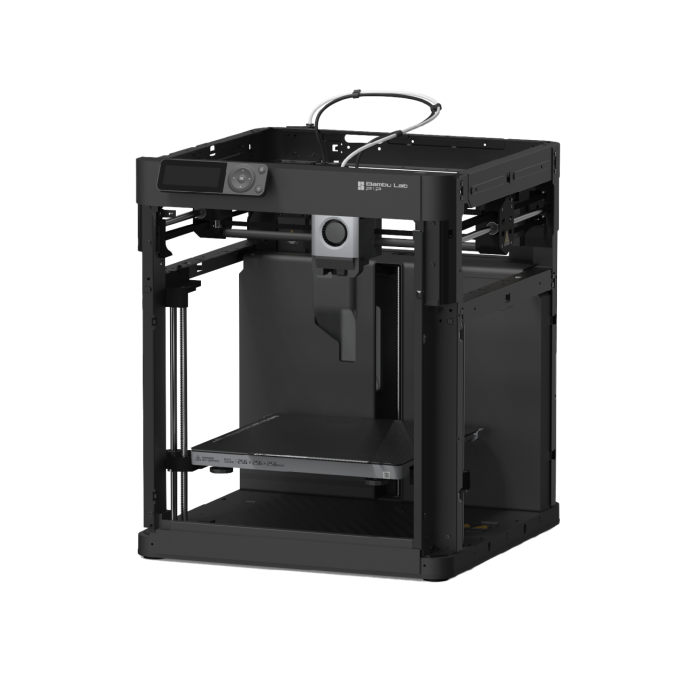

- For X1 Series-1.png)

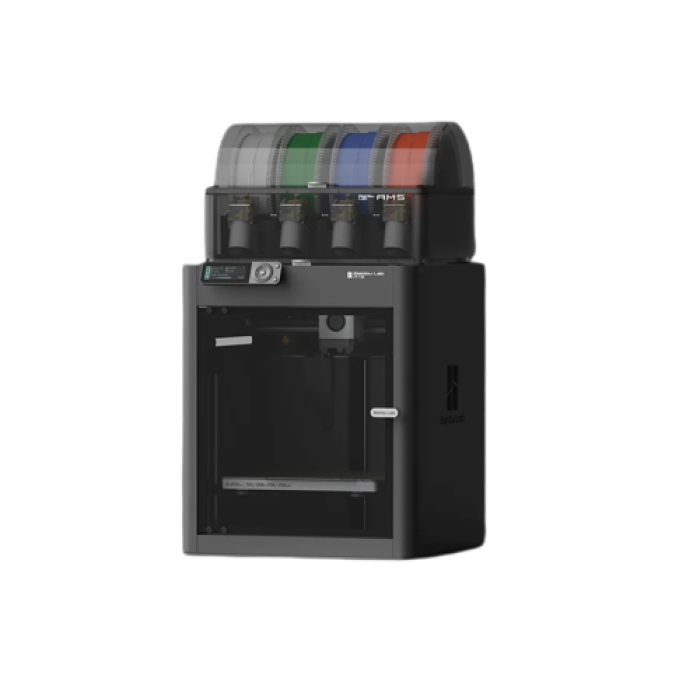

- For AMS inside.png)

-4.jpg)

-4.png)

-4.png)

-3.png)