Call Us

+971 55 414 2197

Free shipping for order over AED 999

We return money within 30 days

Friendly 24/7 customer support

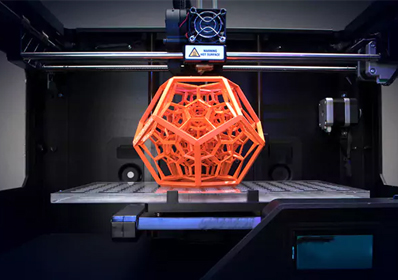

3D Printing Services

Indeed, one of the advantages of 3D printing or additive manufacturing is its potential to reduce the need for extensive human labour in certain manufacturing processes. Here are a few reasons why 3D printing can lead to less human labour:

- Automation: 3D printing processes are largely automated. Once the design is input into the printer, the machine can carry out the printing process with minimal human intervention. This reduces the need for manual labour in the actual manufacturing process.

- Batch Production: 3D printers can be programmed to produce multiple copies of the same object or various objects within a single print run. This batch production capability further minimizes the need for constant human oversight, particularly compared to traditional manufacturing methods where each item might require individual attention.

- Reduced Assembly: In some cases, 3D printing can produce complex parts or products in a single piece, eliminating the need for assembly lines and reducing the associated labor requirements.

- Remote Monitoring: Many 3D printers can be monitored and controlled remotely. This means that a single operator can oversee multiple printers from a central location, reducing the need for on-site personnel.

While 3D printing does reduce the need for certain types of labour, it's important to note that this doesn't mean a complete elimination of jobs. Instead, it often shifts the nature of the required skills, creating demand for professionals who can design and optimize 3D models, maintain, and troubleshoot 3D printers, and manage the overall manufacturing process. Additionally, industries still require skilled workers for post-processing tasks, quality control, and other related activities.