PETG-CF

• Bambu PETG-CF needs proper drying before printing. Drying conditions: 65℃ for 8 hrs. Store in a dry environment after use. Dry before use if the material absorbs moisture. For more details please refer to: Filament drying instructions on WIKI. • To get stronger Z-adhesion, please set a higher infill density, and do not use an open-frame printer or set too large fan percentages to avoid over cooling. • To get shinier looks, set lower speeds and relatively higher temperatures.

Product Features

Features

- Less Clumping and Stringing

- Premium Print Surface

- Improved Mechanical Properties & High Flexibility

- Comes with Basic Reusable Spool

- Diameter: 1.75mm +/- 0.03mm

Shipping Weight

- 1.400 Kg

Description

Bambu PETG-CF: Elevate Your 3D Prints with Carbon Fiber Excellence

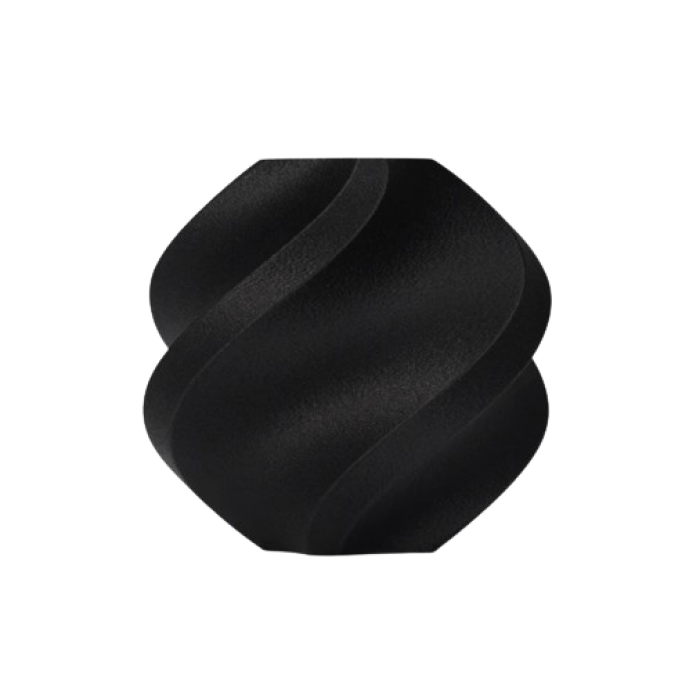

Introducing Bambu PETG-CF, a cutting-edge composite material that combines PETG and carbon fiber to redefine the standards of 3D printing. This filament boasts a new formula that significantly enhances printing quality by addressing nozzle clogging and clumping issues commonly associated with traditional PETG. With the infusion of carbon fiber, Bambu PETG-CF not only improves strength but also maintains exceptional toughness and a shiny finish, making it the go-to material for drone parts, racing models, and various functional components that demand high performance, especially in impact strength, coupled with a sleek appearance.

Key Features:

1. Less Clumping and Stringing: Streamlined Printing Process

Bambu PETG-CF is engineered with a modified formula that specifically targets clumping and sticking to the nozzle during PETG printing. Experience a streamlined printing process with reduced clumping and stringing, ensuring optimal printing performance with every layer.

2. Premium Print Surface: Carbon Fiber Excellence

The addition of carbon fiber to Bambu PETG-CF brings an advanced texture to the print surface. Revel in a premium print surface that not only exhibits the shine of PETG but also incorporates the unique characteristics of carbon fiber, resulting in minimal layer lines and a delicate texture.

3. Carbon Fiber Texture: Unique Aesthetic Appeal

Experience the distinctive aesthetic appeal of Bambu PETG-CF with its carbon fiber texture. This filament introduces soft reflection, minimal layer lines, and a unique delicate texture, setting it apart from conventional materials and offering a visual treat for your 3D prints.

4. Shiny Finish: Versatile Aesthetics

Unlike PLA-CF's matte finish, Bambu PETG-CF presents a shiny finish, providing an additional choice for versatile aesthetics in your 3D prints. Enjoy the sleek and polished appearance that enhances the overall appeal of your creations.

5. High Flexibility: Exceptional Toughness

Compared to other carbon fiber materials, Bambu PETG-CF exhibits exceptional toughness, making it less prone to fracture under external stress and impact. Embrace the durability and resilience of this filament, ensuring that your prints withstand the rigors of real-world applications.

Redefine 3D Printing with Bambu PETG-CF

In conclusion, Bambu PETG-CF stands as a revolutionary filament that elevates the standards of 3D printing. Addressing common PETG challenges, this filament combines strength, toughness, and a shiny finish, making it an ideal choice for high-performance applications with a sleek appearance. Redefine your 3D printing experience, explore unique textures, and enjoy the exceptional qualities of Bambu PETG-CF in every intricate detail of your creations.

Specification

Parameters

Recommended Printing Settings

Physical Properties

Mechanical Properties

.png)

-3.png)

-14.png)

-1.png)

-8.png)

-2.png)

-2.png)

-1.png)

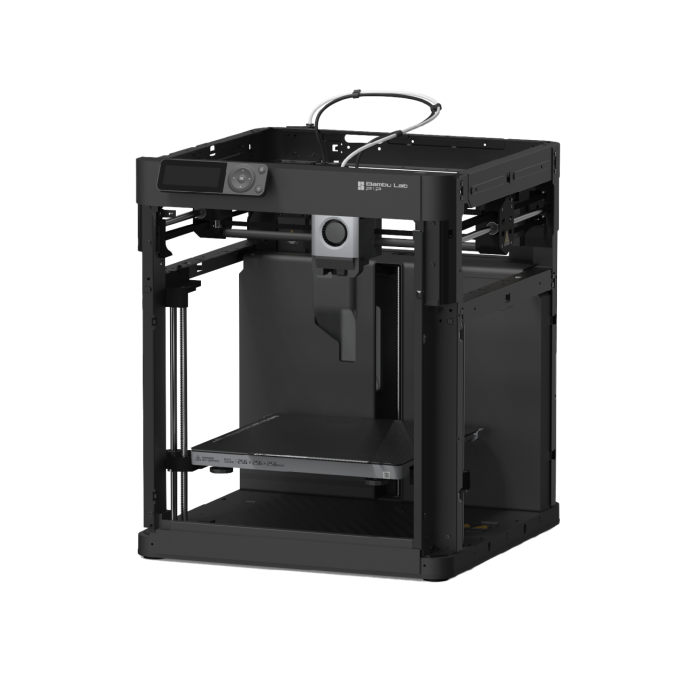

- For X1 Series-1.png)

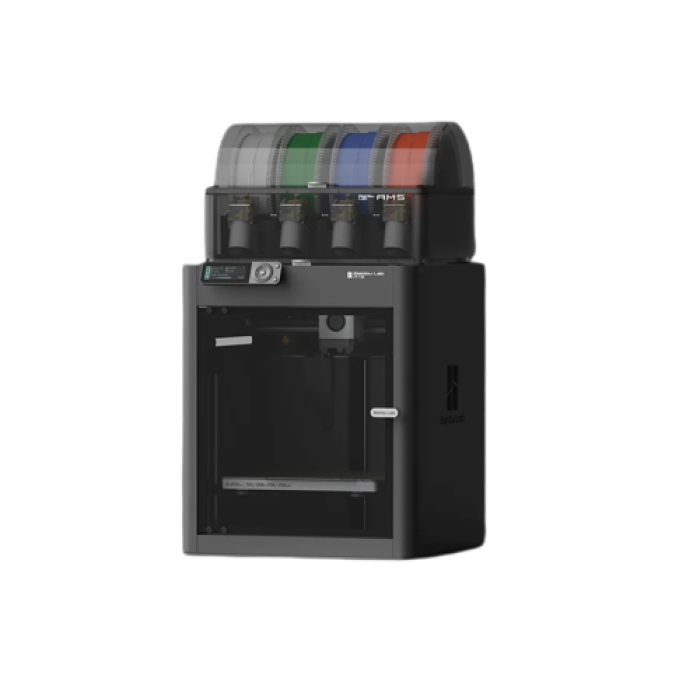

- For AMS inside.png)

-4.jpg)

-4.png)

-4.png)

-3.png)